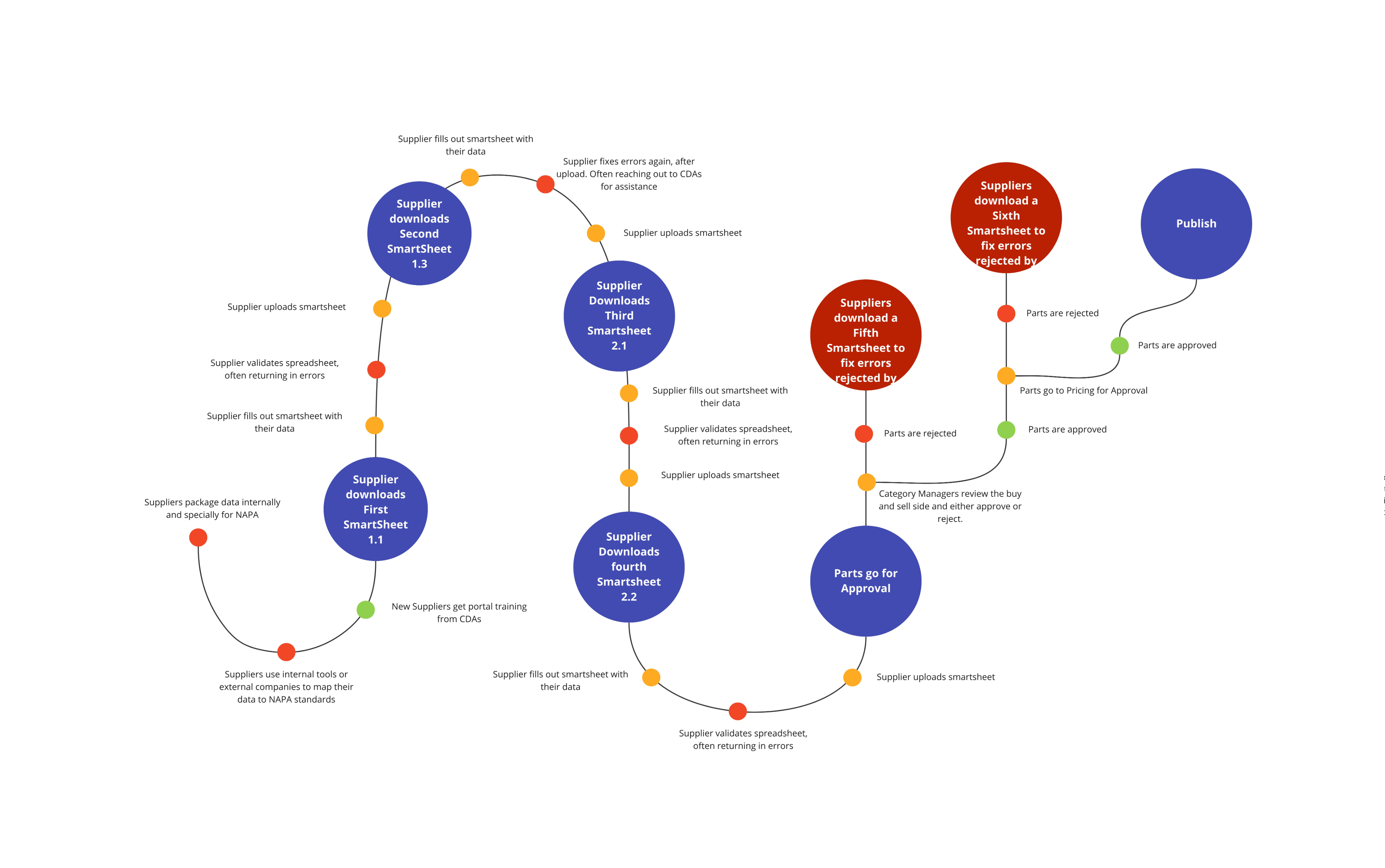

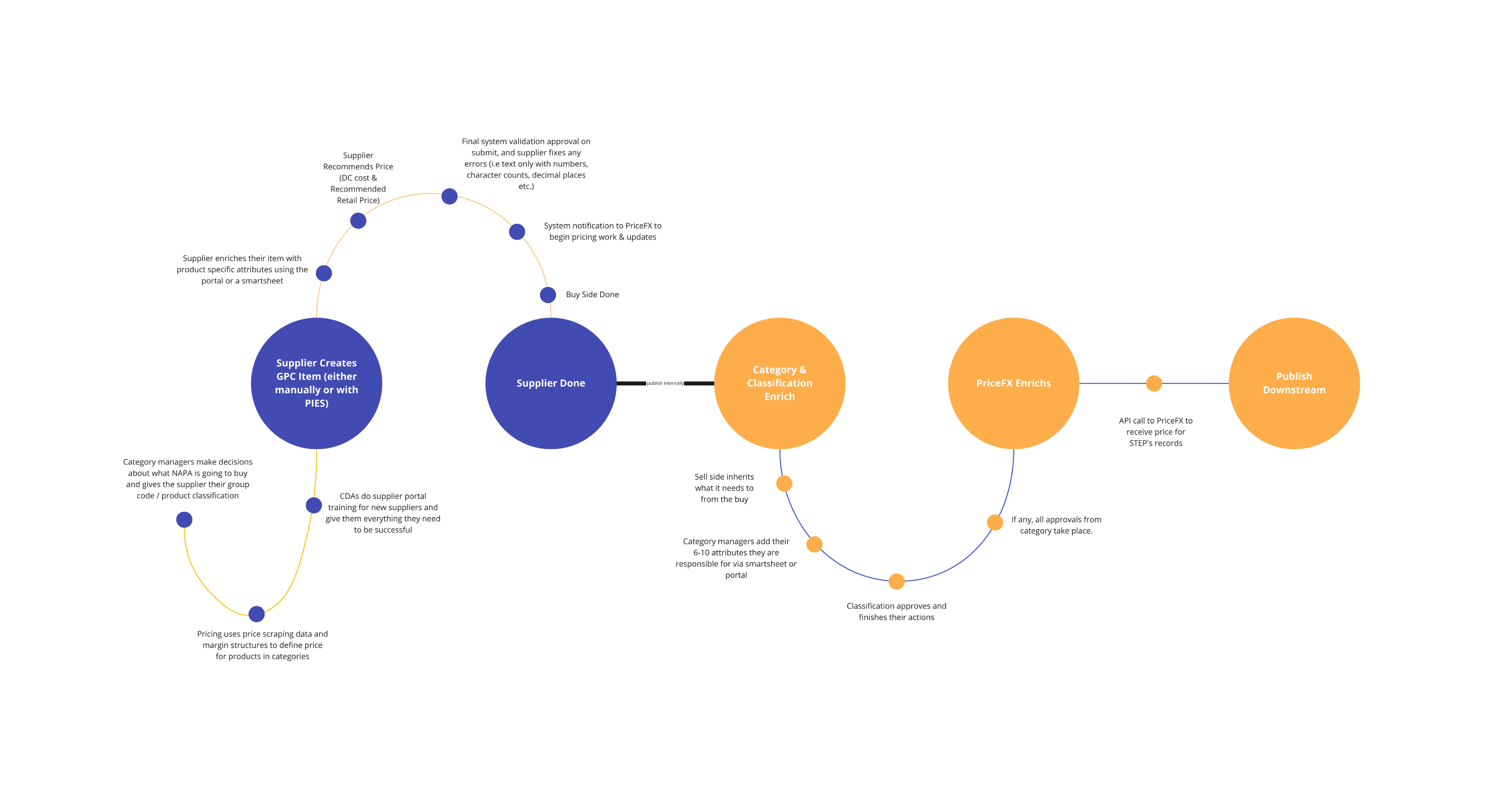

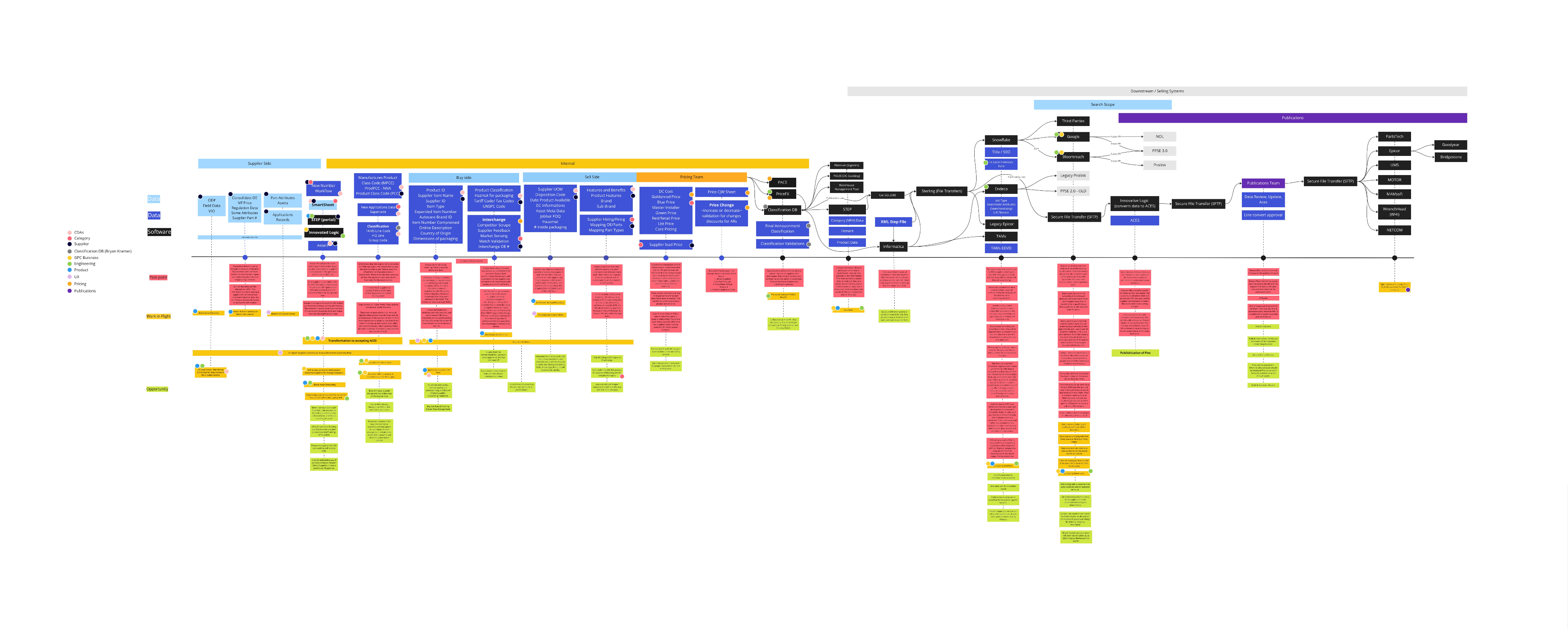

In the auto part industry, there is what comes with the car (OE - Original Equipment) and something a manufacturer has made to rebrand what came in the car AE( After Market Equipment). This goes for farming equipment, fleet vehicles, industry specific vehicles (ambulances, firetrucks, etc) but our main focus for this project was to focus on the average consumer / driver. NAPA stores support this industry by selling car parts from multiple suppliers, to multiple car repair shops and the hobbyist customer coming into a retail store. NAPA does not manufacture parts itself, so it partners with these manufacturers we call suppliers. These suppliers not only sell us the part for resale but have to tell NAPA's back end system all of the information about the part, what cars the part fits (or doesn't fit), and equivalent parts out there (interchange number). This is just a little context needed to understand the challenge.

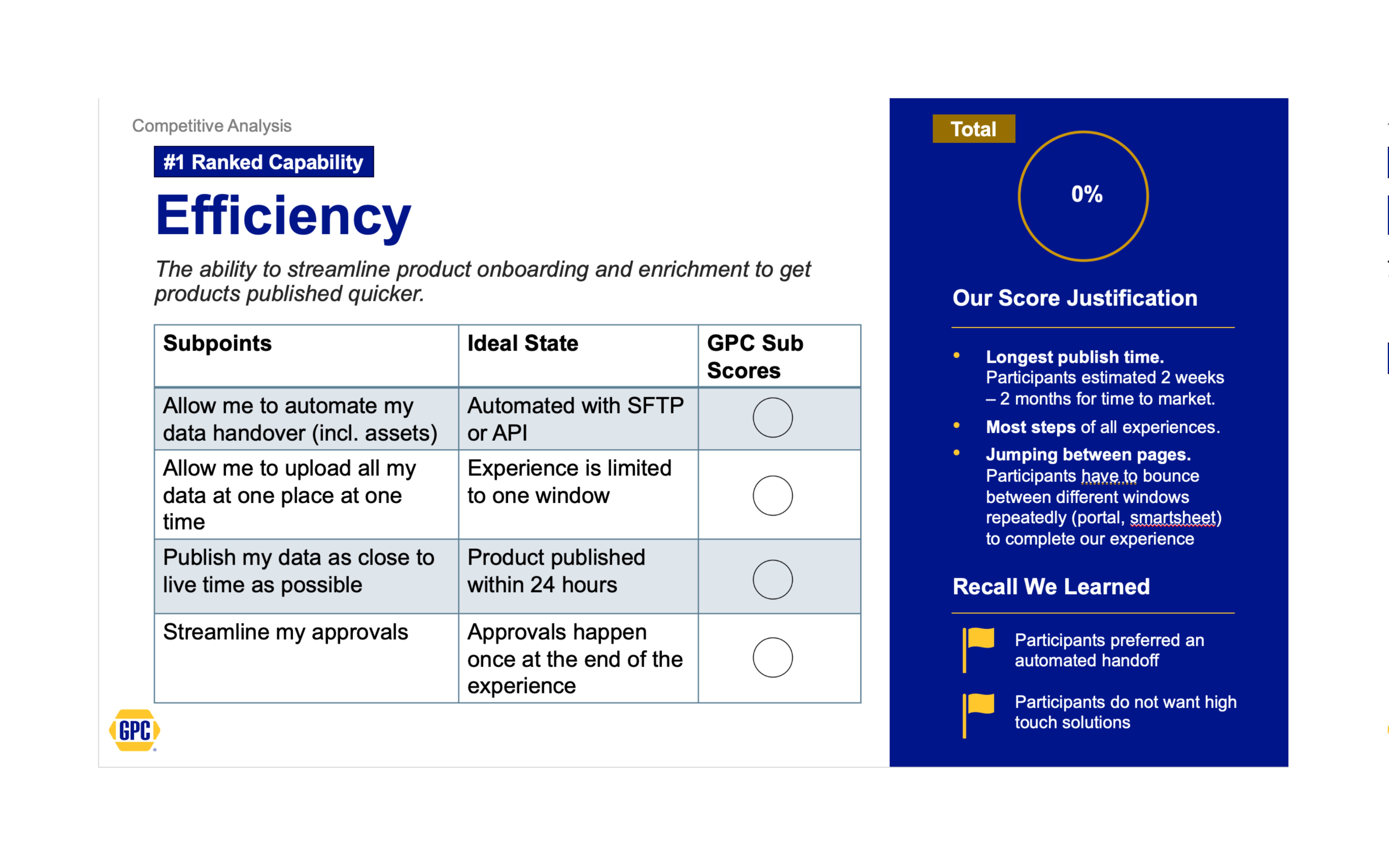

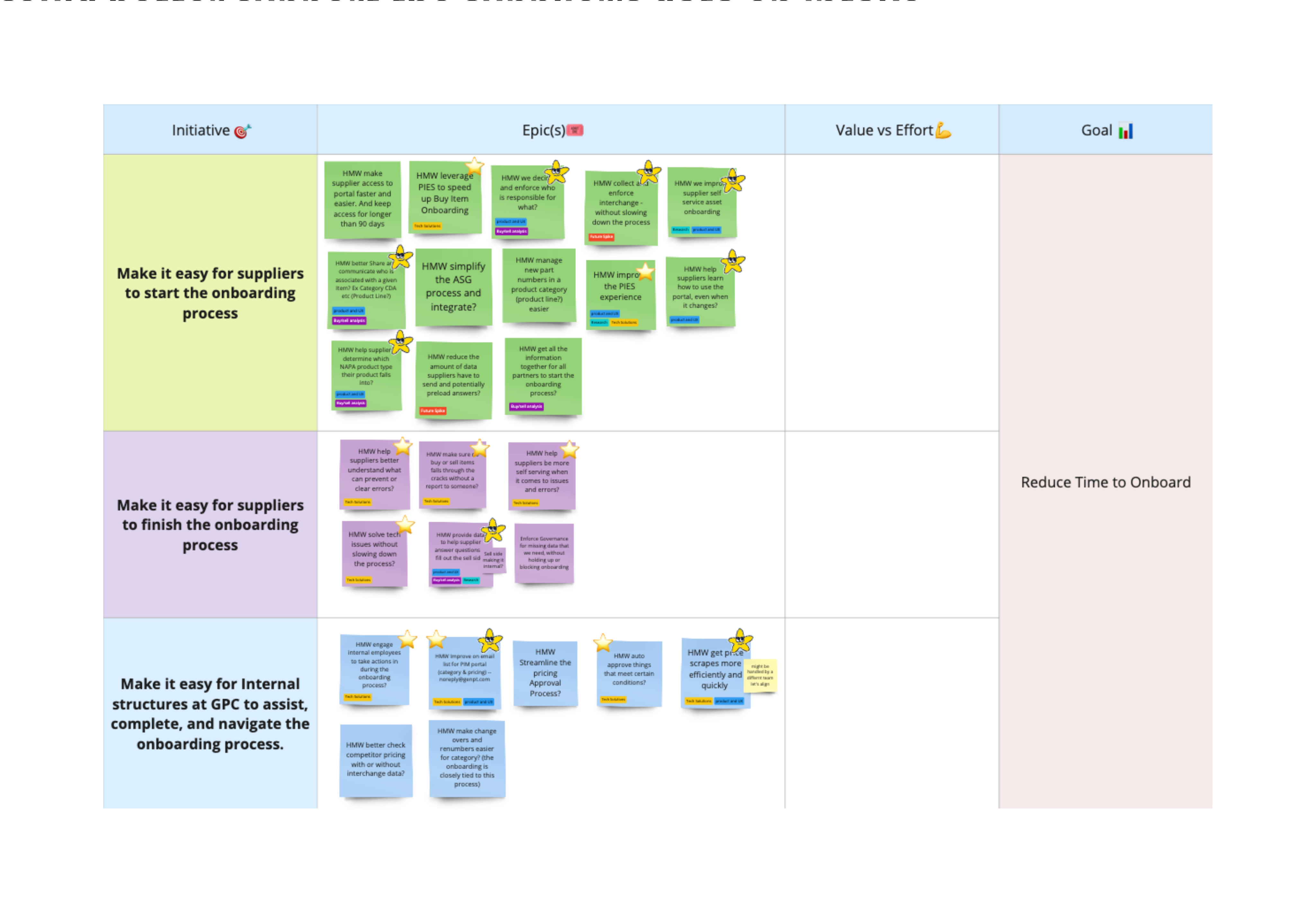

The technology used to hand over information from supplier to NAPA is legacy and difficult to use for both the suppliers and internal employees trying to read the information and manage it. The clunky back end software also had very little reports or quality control. This industry relies heavily on the correct information being published to the retailer websites. If even a few words or numbers are wrong, the part could be mislabeled on the shelf, not only leading to things like loss of sale but also the breakdown of the customer's car. This problem for the industry has compounded over the years leading to perception around brands for having "good" data online, or "bad" data. Fixing a car is no easy task, and the parts are supplied from all over. The organization sought to reduce the cognitive load on both parties in order to load and manage the data faster, with more efficiency and especially to present correctness.